The EnMS Audit Guideline was created to assist energy user organisations to implement an effective internal EnMS audit following requirements of ISO 50001 Clause 4"Energy management system requirements", sub-clause 4.6 "Checking (performance)", item 4.6.3 "Internal audit of the EnMS". To be more specific, it guides to execute a proper audit to assure "conforming to planned arrangements for energy management including the requirements of this International Standard" and "being effectively implemented and maintained"

The EnMS Audit Guideline was created to assist energy user organisations to implement an effective internal EnMS audit following requirements of ISO 50001 Clause 4"Energy management system requirements", sub-clause 4.6 "Checking (performance)", item 4.6.3 "Internal audit of the EnMS". To be more specific, it guides to execute a proper audit to assure "conforming to planned arrangements for energy management including the requirements of this International Standard" and "being effectively implemented and maintained"

Up to this point, it is not much different from other management system.

However, "this International Standard" refers to ISO 50001, and EnMS operation is unique to other management system with a prime objective to improve energy performance. For this reason, in order for the EnMS audit to meet the objective, it not only to assess the operational and documentation aspects, but also to assess an organisation's energy performance.

The SEP program best performance scorecard endorced by the U.S.A. DOE and USCEEM requires assessment by a

performance verifier as well as by a lead auditor when using the scorecard for certification.

An interesting question related to EnMS audit is when after setting an energy consumption reduction target at "5%", and only achieved "3%", would the assessor place a "nonconformance"card? Answer is "No". Comparing to Targeting "1%" and achieved "1%", "only achieved 3%" provides much more benefit to the organisation business.

Understanding the importance of performance verification in the EnMS, important elements in EnMS audit can be listed as below:

Understanding the importance of performance verification in the EnMS, important elements in EnMS audit can be listed as below:

(1) To fully appreciate the contents of energy review conducted.

Specifically to understand the what are organization's energy

performance improvement opportunities, and how the baseline

is defined and how it was related to the targets

(undertand the background of defned EnPI),

(2) To fully appreciate the contents of EnMS Action Plan.

Specifically, assessment is to focus how energy review results

are reflected in the planned actions.

When audit is executed in accordance to the perviously

mentioned items (1) and (2), it becomes clear about the

intensity of the organisation's EnMS operation, and can

identify useful audit findings.

Additional important item is,

(3) To fully understand the effectiveness of M&T activities

When quantatitatively assessing energy performance, data

collection and monitoring status of EnPI through "Miyeru-ka"

are crucial in identifying the improvement as well as to secure

evidences. More established the M&T activity and system,

it attracts assessor for favourable evaluation.

One final important item is,

(4) To understand continuous improvement procedure and its

intensity

Often overlooked element in EnMS energy performance improvement is "once energy performance improvement is achieved, the value of how to maitain the best condition after the improvement".In order to maintain the best condition is not an easy task. It often requires stronger effort than to engage in an improvement activity. Why not interpret as "To maintain the best condition" = "continuous improvement"?

When an organisation positively takes a course in sustainable business development, our view is that there should hardly be any "non-conformance" cases during the EnMS audit. By stating this, one might say "then EnMS auditor task is not difficult". On the contrarily, we believe the degree of difficulty with EnMS auditors are much higher than that of other energy management system. There are various reasons but the main should be that EnMS auditors have to discuss about the superiority of the business objectives and targets related to energy performance improvement on a equal basis with the top management officers of the organisation.。

EnMS Audit Guideline (Document ID: EnMS-Audit.Gdln-M01E)

EnMS Audit Guideline using a scorecard system can be used as a guide book for auditee how to face an EnMS audit without having to fully mastering the ISO 50001 requirements. The guideline is proposing a paradigm shift: "It is not to master EnMS to implement audit, it is through implementing audit to master EnMS". Questions such as, where are the energy performance opportunities; how to capitalise the opportunities; how to set up targets; what are the results expected and how to measure; etc., through EnMS audit, there are endless topics of positive aspects. With EnMS audit, the main player is no longer auditor but is auditee, au ultimate aim is to boost energy user motivation. By capitalising the guideline, you will see an interesting “auditee audits auditor" situation. This is because 70% of the task of EnMS audit is to verify energy performance improvement with related document review. View Document Samples...

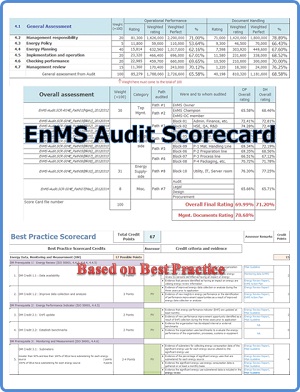

EnMS Audit Scorecard (Tool ID: EnMS-Audit.SCR-R04E)

It uses a model business unit to demonstrate actual scoring practice thus presenting useful audit interview questions for all ISO 50001 requirement items. Based on the answers to questions, assessor is to score to the scale of "0 - 10". After interview session is completed, the scoring will be consolidated into the rating of "0 - 100%", to summarising the intensity of the EnMS operation as well as the level of energy performance improvement. By using the scorecard system, the preparation for audit activities is greatly enhanced to provide highly efficient audit proceedings, and the quantitative assessment provides transparency to encourage auditee to commence improvement activities without delay. View Scorecard Samples...

Menu a la carte

● M20 EnMS Audit Guideline (word file) 60.00 USD (pdf file) 50.00 USD

● R218 EnMS Audit Scorecard (1 word file, 13 excel files) 90.00 USD

Set menu

● M555 Set menu Audit-M&V Guideline with Scorecard (Package of M20 and R218) 120.00 USD

With above audit set and below "a powerful set containing key 12 management documents for ISO 50001 compatible operation" making "Self-declaration" within reach.

● M333J Set menu #101, "All 12 in one" 180.00 USD

"All 12 in one" brochure available DOWNLOAD for your reference

The Japanese monthly magazine "ISOS" is a well-known ISO dedicated publication to provide latest ISO related information on activities, studies, and developments in Japanese. In the March edition of "ISOS", the interview article with an U.S.A. ISO/TC242 expert provided a very clear picture about SEP and its programs currently being promoted by USCEEM and DOE in the U.S.A. This article should stimulate Japanese readers who are struggling in tackling with ISO 50001 international standard with some new ideas given by the SEP program. We believe it is also a good reference to those who are not yet familiar with SEP program, and therefore would like to introduce summary of the message coming from the article.

The expsert urges Japanese industries to adopt ISO 50001 which is a beneficial tool to enhance Japan's leading role in energy saving technology through energy management aspects in the global scene. The part that will generate ISO 50001 awareness in Japan is where the expert speaks about SEP's drive to improve energy performance improvement and the certification part should come with the performance. He elaborated this from the perspective of both ISO and SEP positions "when implementing ISO 50001, there is an option for energy users to self-declare conformance".

The article also provides overview of the following three key SEP programs:

a) Energy performance verification standardization scheme

b) Energy management scorecard scheme for performance ranking

c) Success stories of significant energy performance improvement results from SEP pilot program

[Go to full article overview page]

EnMS-Doc is putting a high value on the fact that through the SEP effort, the U.S. government is addressing energy management operation as a priority and focal point for the industrial sector to build up competitive advantage in the global scene. EnMS-Doc will continue to follow SEP updates and plan to provide timely key information to our visitors.

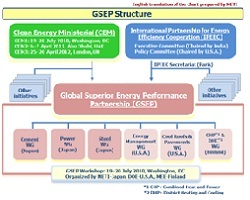

In the article, the expert also introduced briefly about GSEP by stating "During the Clean Energy Ministerial (CEM) took place in July 2010, Global Superior Energy Performance Partnership (GSEP) was founded as an Japan-U.S.A. initiative related to energy conservation (refer to the chart on the right prepared by METI, Japan). In GSEP, there are 6 ongoing working groups (WG), and 3 WGs (Cement, Power, Steal) chaired by Japan, 2 WG (EnMS certification, Cool Roofs and Pavements) chaired by the U.S.A. and 1 WG (Combined Heat and Power and Efficient District Heating and Cooling) chaired Finland. The WG are liaised with METI for Japan, DOE for the U.S.A. and Ministry of Employment and the Economy for Finland."

In the article, the expert also introduced briefly about GSEP by stating "During the Clean Energy Ministerial (CEM) took place in July 2010, Global Superior Energy Performance Partnership (GSEP) was founded as an Japan-U.S.A. initiative related to energy conservation (refer to the chart on the right prepared by METI, Japan). In GSEP, there are 6 ongoing working groups (WG), and 3 WGs (Cement, Power, Steal) chaired by Japan, 2 WG (EnMS certification, Cool Roofs and Pavements) chaired by the U.S.A. and 1 WG (Combined Heat and Power and Efficient District Heating and Cooling) chaired Finland. The WG are liaised with METI for Japan, DOE for the U.S.A. and Ministry of Employment and the Economy for Finland."

[Page showing enlarged chart]

By the way, listed below is three important meetings related to GSEP held in March and April:

12-13 March 2012 Tokyo, Japan "GSEP Sectoral Working Group Sessions (Power, Steel and Cement WG)

22-23 March 2012 Seoul, Korea "GSEP Energy Management Working Group Meeting"

25-26 April 2012 London, UK "Clean Energy Ministerial 3 (CEM3)"

In the same March edition of "ISOS" also features "Business Continuity Management: The latest ISO standard trend and key elements to adopt BSMS". When observing the BSMS, you will appreciate very much that "Energy Management" and "Business Continuity" are linked by fate. "Business Continuity" is a globally hot topics today because from the recent global experiences, people are realising that "without energy you cannot sustain the business". Once you are adopting ISO 50001 based energy management operation, automatically you are advancing to manage the business continuity aspects. The 12 management documents that are offered from our menu pages designed to ensure ISO 50001 compatible energy management operation are receiving very favourable review for their nature of coherency in guiding towards business continuity management.

In the same March edition of "ISOS" also features "Business Continuity Management: The latest ISO standard trend and key elements to adopt BSMS". When observing the BSMS, you will appreciate very much that "Energy Management" and "Business Continuity" are linked by fate. "Business Continuity" is a globally hot topics today because from the recent global experiences, people are realising that "without energy you cannot sustain the business". Once you are adopting ISO 50001 based energy management operation, automatically you are advancing to manage the business continuity aspects. The 12 management documents that are offered from our menu pages designed to ensure ISO 50001 compatible energy management operation are receiving very favourable review for their nature of coherency in guiding towards business continuity management.

(1) The prime purpose of energy management is to continual improvement of energy performance, and if the system is valid,

it automatically complies to ISO 50001 standard, and therefore principally it provides "self certification" framework.

(2) Since it is the international standard, it provide the system to quantify and verify the energy performance improvement at

the universal scale no matter where your business units are located globally or locally.

(3) Person(s) responsible for leading the EnMS operation has the role and responsibility to create and maintain the

management documents including "EmNS Charter" to ensure the operation is ISO 50001 compatible, and so the

organization is comfortable in self certifying.